- +86 19332588152

- sales05@fuootech.com

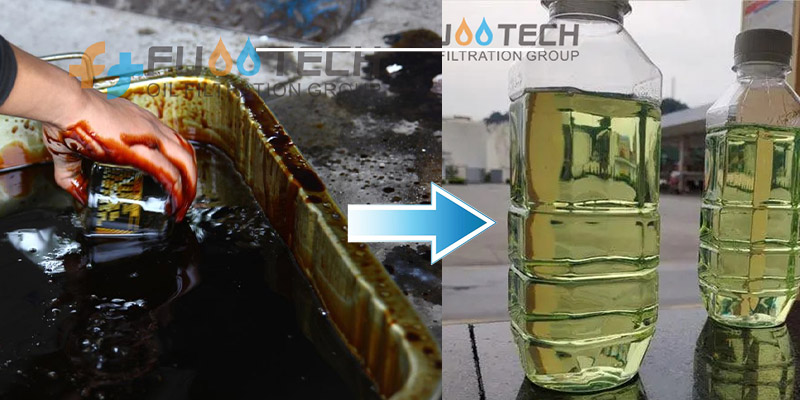

FUOOTECH Group combined with Fangsheng is the top manufacturer of waste oil distillation & re-refining plant; Our plant can distillate & re-refine waste engine oil, waste gear oil, waste crankcase oil, waste hydraulic oil, tyre pyrolysis oil, plastic pyrolysis oil, rubber pyrolysis oil and other wastes fluids to diesel oil or base oil. Such plants have been exported to more than 40 countries and regions, and the 90% of orders are complete turnkey project.

In 2023, the 6th-generation waste oil regenerative distillation re-refining plant successfully developed by our company was perfectly combined with the most advanced anaerobic pyrolysis separation technology of hazardous waste which was developed at the same year, helps the waste oil regeneration ratio increased upto 99.9% max. (other company’s products only produce the around 70% of oils), therefore, our plant can bring more benefits to customers.

It is very suitable for large and small repair shops, various general machinery, ships, trucks and other heavy pollution (that is, dirty oil and mixed oil that cannot be treated by chemical methods).Specification

|

Parameters |

Unit |

Model Names |

||||||

|

FS-HDM-1 |

FS-HDM-2 |

FS-HDM-3 |

FS-HDM-4 |

FS-HDM-5 |

FS-HDM-6 |

FS-HDM-7 |

||

|

Treatment Capacity |

Tons/day (24 hours continuously) |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

|

Oil Production Rate |

% |

More than 98% (along with our Anaerobic Pyrolysis Separation System of Hazardous Waste) |

||||||

|

Raw Materials |

|

waste engine oil, Tire/plastic pyrolysis oil, waste lube oil, waste motor oil, heavy oil, crude oil, etc |

||||||

|

Outputs |

|

Only Refined oil products & small quantity of Carbon powder (along with our Anaerobic Pyrolysis Separation System of Hazardous Waste) |

||||||

|

Avg. Power |

Kw/h |

55 |

66 |

95 |

135 |

180 |

230 |

280 |

|

Vacuum Degree |

Mpa |

≤-0.015~-0.1 |

||||||

|

Working Oil Temp. |

℃ |

175 ~ 550 |

||||||

|

Power Supply |

V |

110/ 220 /380 /415 / 440 V, 3Phase, 50Hz or as per request |

||||||

|

Noise |

db(A) |

≤80 |

||||||

|

Running Process |

|

Continuous |

||||||

FUOOTECH reserves the rights to any upgrading without notification.

THE MOST ADVANCED TECHNOLOGIESAND FEATURES ON FS-HDM PLANT:

1. Full-bridge Rectification Distillation Technology - a patented complete new distillation technology

2.Self-developed flocculant

3.Anaerobic Pyrolysis Separation System of Hazardous Waste - Increase the Oil Production Rate and Reduce the Wastes to Minimum

4.Self-developed main reactor material

5.Self-developed electromagnetic coil

6.Advanced catalytic adsorption systems

7.Waste gas (non-condensable gas) treatment system

8. Keep the carbon chain constant during the distillation process and only obtain the base oil or diesel oil by our special technology.

9.Multi Heating Way Available

10. Make full use of the reflux device to suppress the production of more light components so as to improve the recovery rate of final oils.

PROJECT CASES: