- +86 135 2739 0908

- sales@fuootech.com

Degassing Device Transformer Oil Purifier Oil Filtration Plant can remove trace water, free water, soluble water, dissolved gas, impurities and tiny particles as well as acetylene, hydrogen, methane and other harmful ingredients effectively and rapidly from used or new transformer oil, so as to improve the flash point, acidity, interfacial tension and dielectric strength value of insulating oil. It suits for purifying all kinds of insulation oils, especially suits for purifying transformer oil from 110KV and above UHV power transmission and distribution projects; also suits for purifying of capacitor oil, mutual inductor oil, switch oil, cable oil.

Oil Results after Filtered by ZYD Series

|

Moisture (Water Content) |

≤ 3 ~ 5 PPM |

|

Gas Content |

≤0.1% (Vol) |

|

Impurities Degree (Filtration precision) |

≤ 1 micron (no free carbon) |

|

Breakdown Voltage (Dielectric) |

≥68 ~ 80 KV |

|

Flash Point |

≥135℃ |

|

Cleanliness |

≤NAS 1638 Grade 6 |

Features

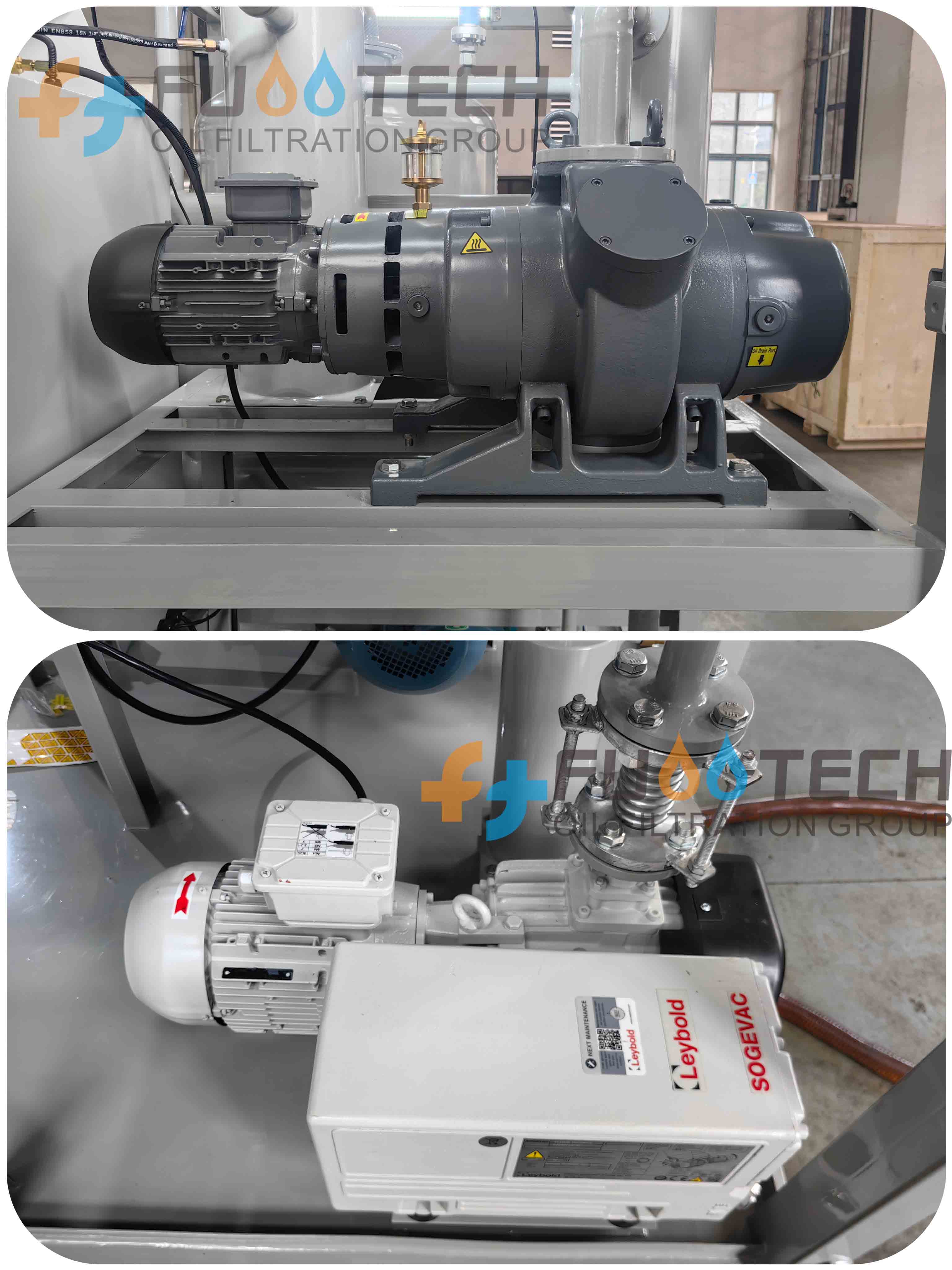

1.Double-stage high vacuum pumping system, strong power of vacuum evacuating, ultimate vacuum value≤ 5Pa.

2. Big capacity of moisture ands gas separating chamber, efficient oil film evaporation, increasing separating size and separating time to ensure the dry-level and dielectric strength of oil improving greatly.

3. Duplex-Stereo film evaporation technology, combined with unique and advanced dewatering, degassing components, rapidly and effectively separate water, gas from oil.

4. Multi-stage precision filtration system, mesh filtration combined with molecular adsorption technologies, maximum remove the particles and impurities.

5. Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

6. Double-safety liquid level controller, pressure protective system and foaming elimination system to ensure machine operating easily and safely.

7. Adopt interlocked protective system, connecting oil discharge pump, heater and liquid level sensor, avoids blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

8. Can be used independent device for vacuuming transformers and vacuum oil filling for power equipment.

9. Can work online for over 150 hours continuously, high reliable and long time running.

Technical Parameters

|

Parameters |

Model Unit |

ZYD-2BY |

ZYD-3BY |

ZYD-6BY |

ZYD-10BY |

ZYD-12BY |

ZYD-15BY |

ZYD-18BY |

|

|

Flow Rate |

L/H |

1800 |

3000 |

6000 |

10000 |

12000 |

15000 |

18000 |

|

|

Working Vacuum Degree |

MPa |

-0.08 ~ -0.099 |

|||||||

|

Working Discharge Pressure |

MPa |

≤ 0.3 |

|||||||

|

Temperature Control Range |

℃ |

20 ~ 80 |

|||||||

|

Operation Temperature |

℃ |

40 ~ 70 (65℃ is best) |

|||||||

|

Power Supply |

|

380V, 50Hz, 3 phases (or as per your requirements) |

|||||||

|

Working hours without Trouble |

Hour |

4000 |

|||||||

|

Continuous Working Hours |

Hour |

150 |

|||||||

|

Ambient Temperature |

|

-25 ~ 55℃ |

|||||||

|

Working Noise |

dB(A) |

65 ~ 90 |

|||||||

|

Heating Power (adjusted available) |

KW |

30 |

36 |

48 |

60 |

72 |

80 |

120 |

|

|

Total Power |

KW |

35.5 |

42 |

52.5 |

68 |

82 |

93 |

135 |

|

|

Inlet/Outlet |

mm |

φ25 |

φ32 |

φ42 |

φ50 |

φ50 |

φ60 |

φ60 |

|

|

Weight |

Kg |

600 |

700 |

1050 |

1150 |

1450 |

1600 |

1950 |

|

|

Dimension |

Length |

mm |

1380 |

1610 |

1750 |

1850 |

1950 |

2050 |

2200 |

|

Width |

mm |

1020 |

1250 |

1350 |

1400 |

1500 |

1600 |

1750 |

|

|

Height |

mm |

1760 |

1950 |

2150 |

2200 |

2300 |

2400 |

2550 |

|

2. All the specs can be customized according to client's requirements.