- +86 135 2739 0908

- sales@fuootech.com

Unlike the traditional method using filtration, this equipment use electrostatic technology to extract all sizes of insoluble contaminants from the oil. The extraction of particle can be as small as 0.01 micron meter. This effectively removes fine particle/ soft contaminant/ varnish from oil, which cannot be removed by any fine filter.

Electrostatic oil cleaning machine is one of the most advance technology to keep your lubrication (mineral oil) clean and long lasting. It also will help your machine free of abrasive materials and enhance the life span of your machine.

This machine is widely used in power plant, turbine lubrication system, Hydraulic Press, Aviation, Construction Machinery, injection mould equipment, rubber moulding plants, Aluminium/ Non Ferous Extrusion, Plywood hot press, servo control hydraulic system, leather processing, shoe making, Mining equipment, automobile industries, steel industries, sugar mill, semi conductor industries, paper manufacturing plants and all types of plants which are using mineral oil for their machines.

Electrostatic Oil Cleaner has proven to be most effective way in modern oil management. It is international widely use now.

Feature & Functions

Ø Low energy consumption, and the online circulation cleaning can be carried out for a long time, so that the oil in the system is always kept clean, and the cleaning process does not affect the normal operation of the main system.

Ø High purification accuracy, can remove particles ranging in size from 0.02µm to 100µm

Ø It can wash out all the sludge and oxides attached to the oil tank, pipe wall and components, truly playing the role of a cleaning system.

Ø Use the advanced electrostatic technology to extract all sizes of insoluble contaminants from the oil, will not block and solve the problem of back pressure and power consumption increase.

Ø No more oil changes.

Ø No attendance required during operation.

Ø Improve performance of hydraulic components to meet high speed & precision demand.

Ø Eliminates oil disposal & recycling problem

Ø Easy to install.

Ø Slowdown of oil ageing process for extension of oil lifespan

Ø Automatic start- and stop-control of the cleaning process by PLC system as option.

Ø Low operation cost.

Ø Reduce power consumption.

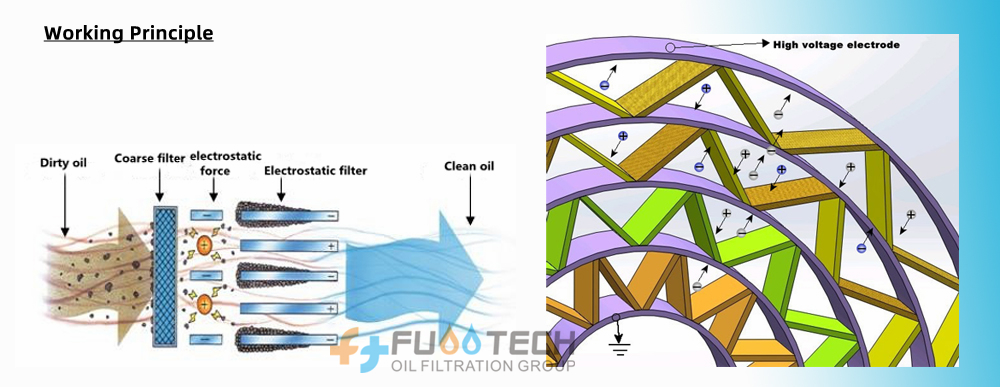

Working Principle

The working of Electrostatic Oil Cleaner is based on the principle of Electrostatics which separates and collect fluid contaminants. The small particles migrate to 'positive' or 'negative' electrodes due to electrostatic force. All the impurities, down to sub-micron levels are removed, also the sludge and varnish, which are so small to see by filters. Basically, the particles below 0.02 micron can be removed. After that, all the contaminant are collected into the 'collectors', where the intensity of the deformed electric field is highest.

After collecting all the impurities, open the drain valve to remove the dirt. Filter elements do not need to be replaced very frequently. The average working life of a cellulose collector is 1500-2000 hours.

Technical Parameters

|

Items |

Unit |

JD-T18 |

JD-T32 |

JD-T40 |

JD-T60 |

JD-T100 |

|

Flow Rate |

L/min |

18 |

32 |

40 |

60 |

100 |

|

Applicable Oil Types |

|

ISO VG 32、46、68、100、etc. |

||||

|

Oil Temperature |

℃ |

40 |

||||

|

Power Supply |

/ |

380V, 50Hz, 3Ph (or as per request) |

||||

|

Total Power |

KW |

0.75 |

1.5 |

1.75 |

2.2 |

3.75 |

|

Oil Hose DN |

mm |

Φ19 |

Φ19 |

Φ25 |

Φ32 |

Φ42 |

|

Dimension (L*W*H) |

mm |

1000 * 700 * 1280 |

1260 * 700 * 1280 |

1350 * 1000 * 1300 |

1370 * 1000 * 1330 |

2100 * 1250 * 1580 |

|

Weight |

Kg |

210 |

330 |

450 |

520 |

600 |

|

Oil Data after Cleaning |

|

Filter Accuracy: 0.02 micron Moisture content: ≤80ppm Cleanliness: ≤NAS 6 grade (1638) |

||||

Note: The dimension and weight will be changed with changing of technical specs.

FUOOTECH reserves the rights to any upgrading without notification.